Features

When we are doing material metallographic testing, Electrolytic Polishing and Grinding Machine can be more efficient compared with traditional mechanical polishing. When we finish polishing, we can jusr turn down the power pressure, and corrosion process will be done by itself in the electrolyte. For laboratory technicians with no experience, they can just follow SOP to get the same result.

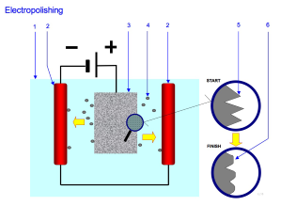

Electropolishing principle

- Electrolyte

- Cathode

- Workpiece to polish (Anode)

- Particle moving from the work-piece to the cathode

- Surface before polishing Surface after polishing

- The principle is to place the workpiece in a special electrolyte and apply an appropriate voltage and current to cause an anode electrolysis reaction on the surface of the workpiece to achieve flattening, glossing and passivation.

- Can make the surface of the parts achieve high cleanliness, high corrosion resistance, and low surface roughness (Ra) in the same time.

- Suitable for precision parts and the areas where is difficult to processed by mechanical polishing.

- Removing the burrs generated after machining, and the surface oxide of the stainless steel parts, achieve a smooth and clean surface.

- Correction of parts dimension precision accurately.

- Electrolysis produces a nickel-enriched and chromium-enriched passivation layer that increases corrosion resistance and improves reflectivity.

Specification

| Timer | 0 ~ 60 minutes |

| Tank capacity | 10 L |

| Tank composition | PVC |

| Maximum amperage | 10A |

| Output | DC 0~140V |

| Wattage | 1.1 kW |

| Dimension | W76*D36*H49 cm |

| Supply power | AC110V |

| Warranty | 1 year |

.jpg)

.jpg)